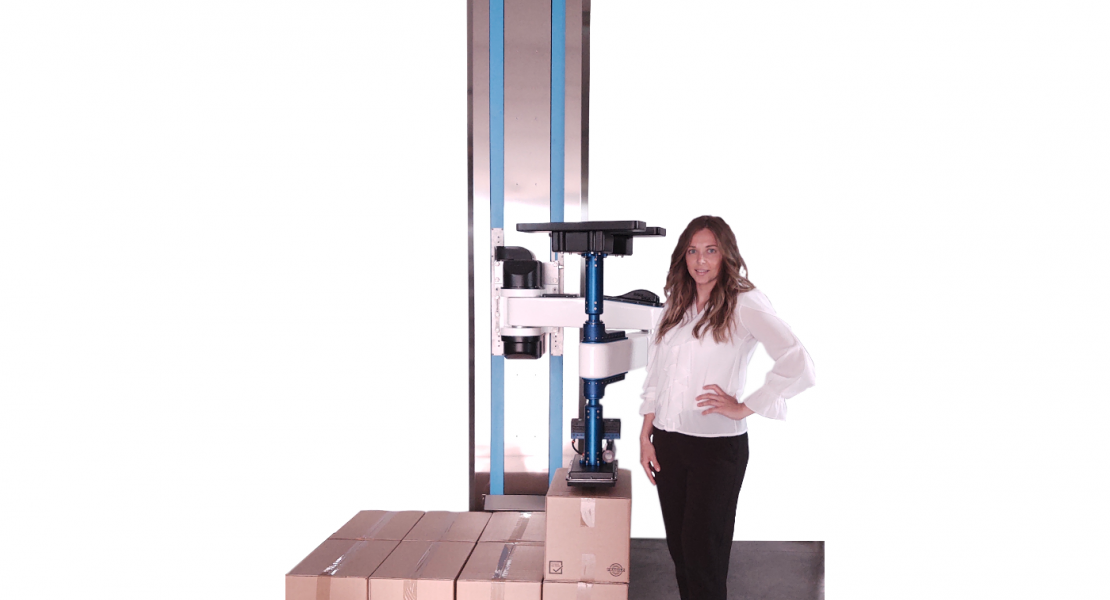

Award-winning quality

All our robots are tested for a long time in our workshop and we only advertise them if they meet all our quality standards. We are also proceeding to certify all our machines at the main European bodies in the field of Clean Design and Safety, clearly in addition to the existing legal certifications.

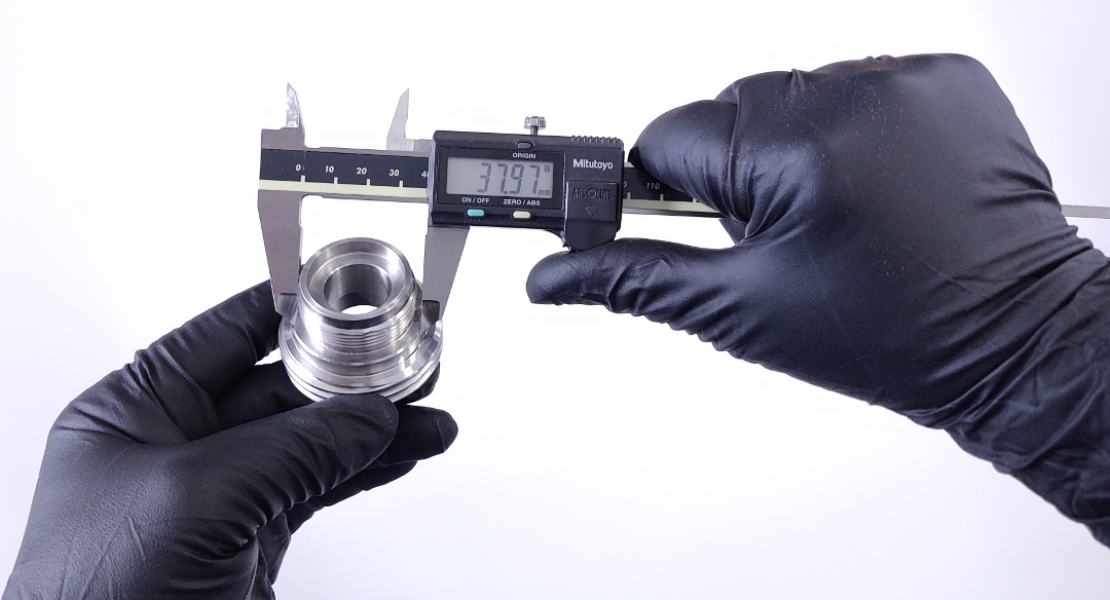

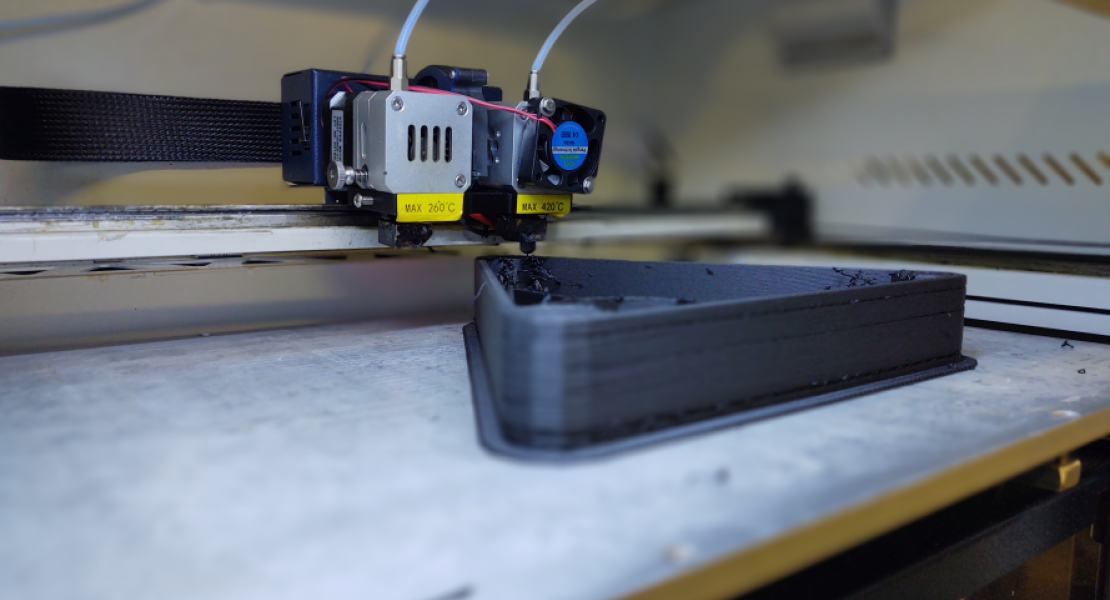

Our components are of proven durability. Over time we have been able to create a skimming among the suppliers, testing the various mechanical and electrical components and selecting the best value for money.