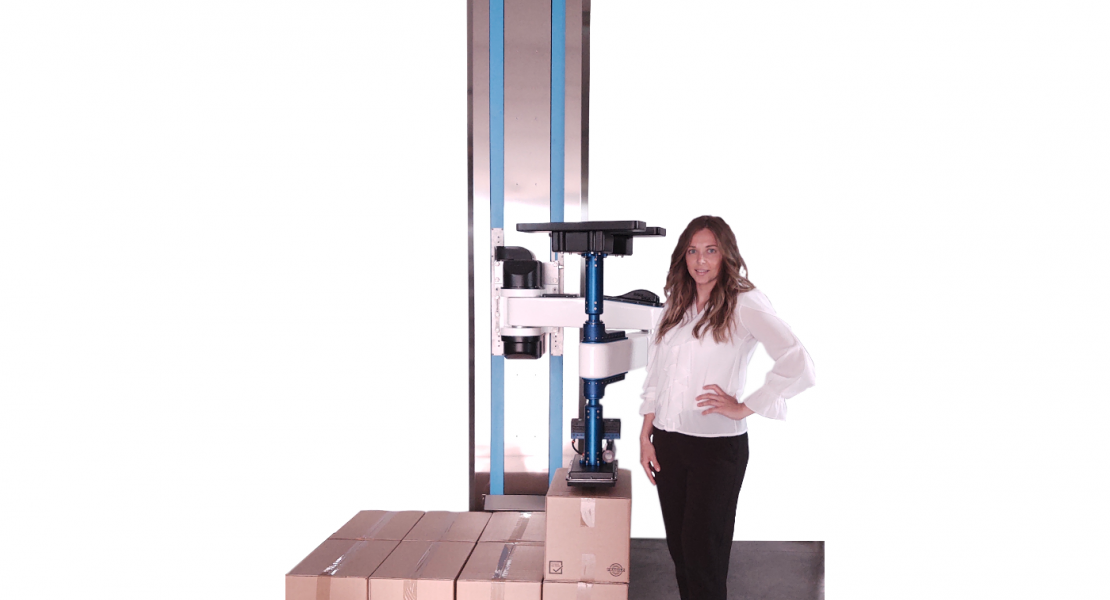

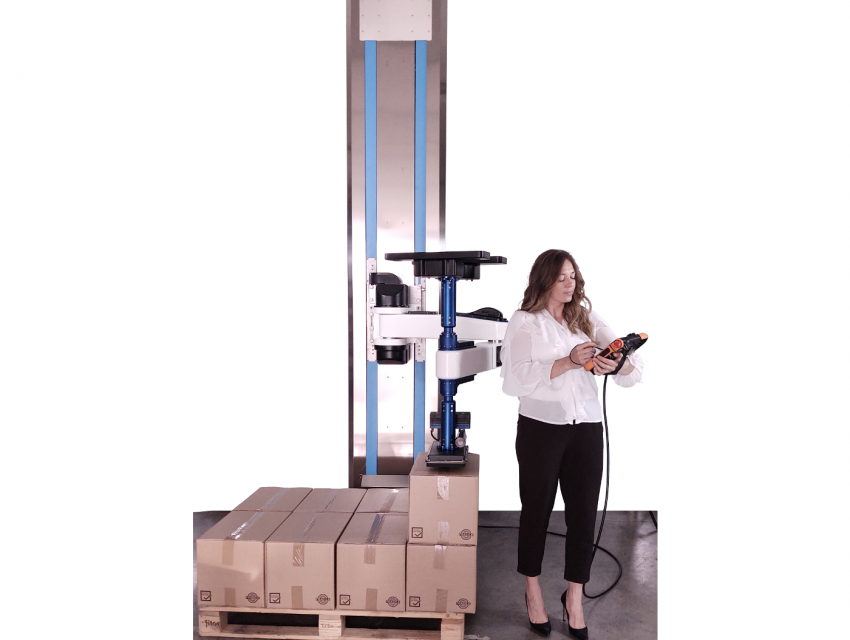

Palletizer KR is a robot designed to make easier the end line operations that primarily concern products packaging. Its wide range of features make it one of the best robots on the market, for both standards and performance.

The KR palletizer has been designed to give maximum performance with the least possible space consumption. With a load capacity of 35 kg for the boxes and a maximum arm width of 1750 mm (KR-L), the robot fully meets the need for functionality and practicality without affecting precious portions of the production surface. Its double grip allows you to take the pallets from a stack without having to have an expensive pallet warehouse, thus also reducing costs.

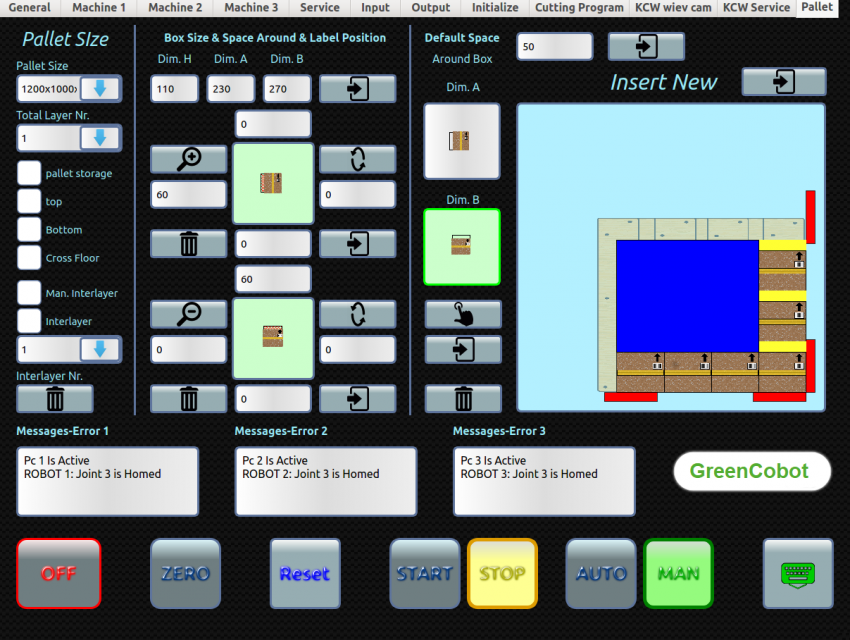

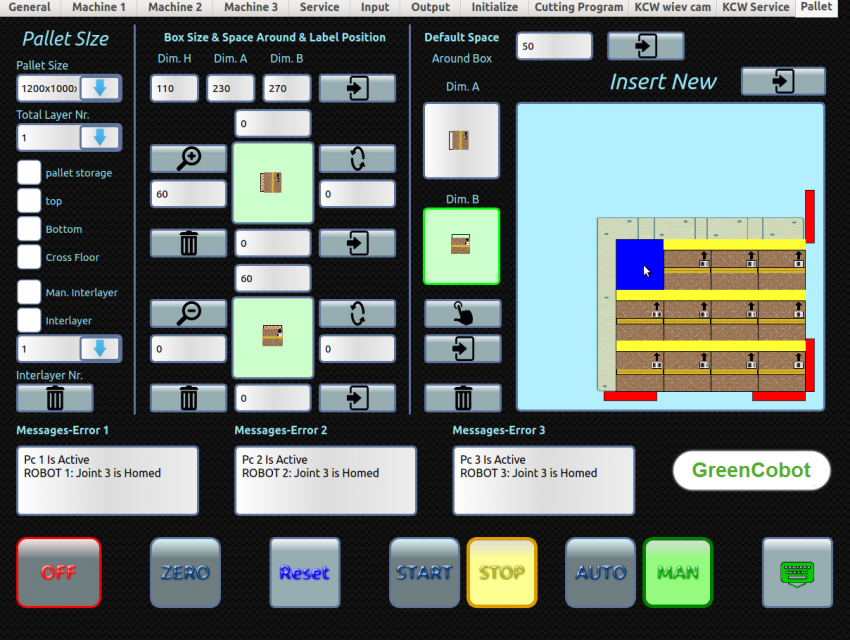

The robot is integrated with the latest generation software designed by GreenCobot to be highly readable and usable even by unskilled users. The interface has simple and intuitive controls that govern the management of one or more robots for palletizing. The software is also characterized by extreme flexibility in program settings.

With a few clicks you can choose a palletization proposed by the program, or compose your own scheme by dragging and hooking the boxes in the chosen positions, with a mode therefore very similar to a smartphone app. With the "crossed levels" command, the machine is able to make a mirrored surface of the pallet to increase its stability; in order to optimize the spaces, the software allows to use special windows for choosing spaces around the boxes.

The GreenCobot KR palletizer is designed to perform normal palletizing tasks very quickly, 860 boxes per hour for single box sockets, and up to 1720 boxes per hour for double box sockets. KR is also able to increase its load capacity to meet particular needs: a greater load implies a lower working speed, but KR is designed in such a way as to have a contained and always predictable loss of speed (up to 20Kg 100 % speed, up to 35Kg 75% of the maximum speed, up to 45Kg 50% maximum speed, etc.), thus making it a robot extremely adaptable to every need.

KR has an excellent error self-diagnosis system, the result of years of development. In fact, the software is able to independently report anomalies and can be further integrated as an option by a vision system that helps the user to receive prompt and immediate remote technical assistance.

The KR palletizer offers wide possibilities for customized installations, such as for example the type of grip (with suction cup, pliers, sack grip, soft-bottomed box grip, etc.). It is provided with a second housing for any other tool.

KR is able to work at full capacity with no more than 2800 watt consumed.

The palletizer can be made and equipped for any need, from the construction materials, the kind of grip and accessories, to the interface.

The very high precision control system uses both an integrated self-diagnosis system and its own database.

Palletizer KR is made by reliable, durable and innovative materials, which guarantee efficiency and speed for the robot's operations. By require, it's also possible to certify it for a use in the food industry.

-

High performance brushless motorization

-

Planetary gearboxes with reduced precision play

-

Integrated management and self-diagnosis system

-

Low consumption

-

Small size

-

Endless customization possibilities

-

Certifiable for food indutries

-

2 models available (KR-M and KR-L)

-

Stainless steel AISI 304 (or 316 if required), anticorodal aluminium and composite fibers

-

Mounting floor

-

6 axes

-

400 kg weight

-

600 mm diameter footprint

-

Voltage 400V 3F+N

-

Power 1400w

-

Signal I/O Std 16+16

-

Max 70dB acoustic noise

-

Max speed 60 pcs/min

The system integrated in each GreenCobot machine is the result of a long period of development which has allowed us to program an intuitive, fast and complete system. The interface clearly presents all the command buttons for each robot on the line, allowing control of more than one at the same time. For those unfamiliar with packaging operations, the software is a valuable aid, thanks to its integrated database in which all the main palletizing programs are present, already preset and ready for use. For those who are already experts, there is the possibility of creating customized palletizing programs, which remain in memory for a future use. The KC management system can be further integrated (as an option) by a vision system which further simplifies remote management and assistance.